ISPE President and CEO Thomas Hartman’s recently published 2024 Pharma Predictions, which originally appeared in Pharma Manufacturing, highlight interesting opportunities for Engineering leaders in pharmaceutical manufacturing. In the statement he expresses that, “This year, COP28 will focus on actionism. Accountability and authenticity will be key to seeing real progress, and part of that accountability will arise from employee-led sustainability initiatives and inter-industry collaboration.” This perfectly captures what we often hear when meeting with life science facility managers and engineers. Actioning sustainability seems to be well prioritized at the corporate level but lacks momentum at the facility level. Additionally, many of the firms we’ve spoken to have allocated 2024 CAPEX to sustainability and decarbonization initiatives but do not yet know how to determine what projects to prioritize to achieve their goals.

Decarbonization as a Key Opportunity for Facilities and Utilities Managers in Pharma

Hartman further stresses that the Life Science industry will continue to be under the microscope and that “accountability and authenticity will be key to seeing real progress.” As a Facilities/Utilities Manager, Energy Engineer, or Project Engineer in a pharmaceutical facility, this presents a unique opportunity. Identifying and proposing decarbonization and sustainability projects can directly influence the flow of capital to your facility. Likewise, at this moment in the sustainability journey for the Life Science Industry as a whole, we need local leaders to become regional and corporate champions armed not just with objectives, but with budget, initiative, and opportunity.

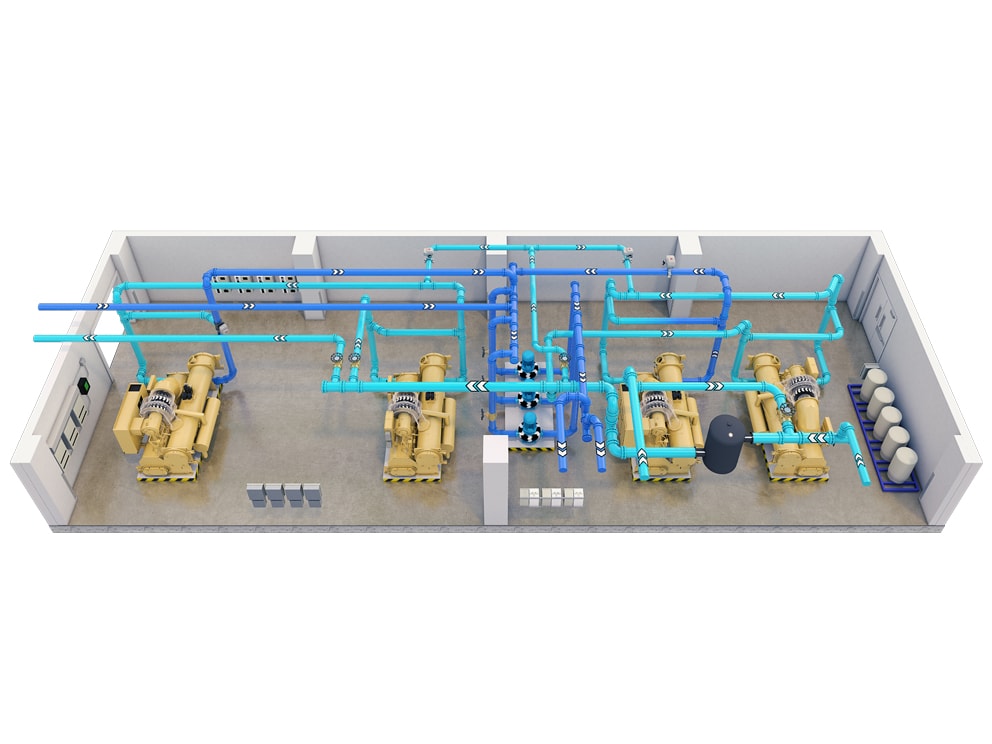

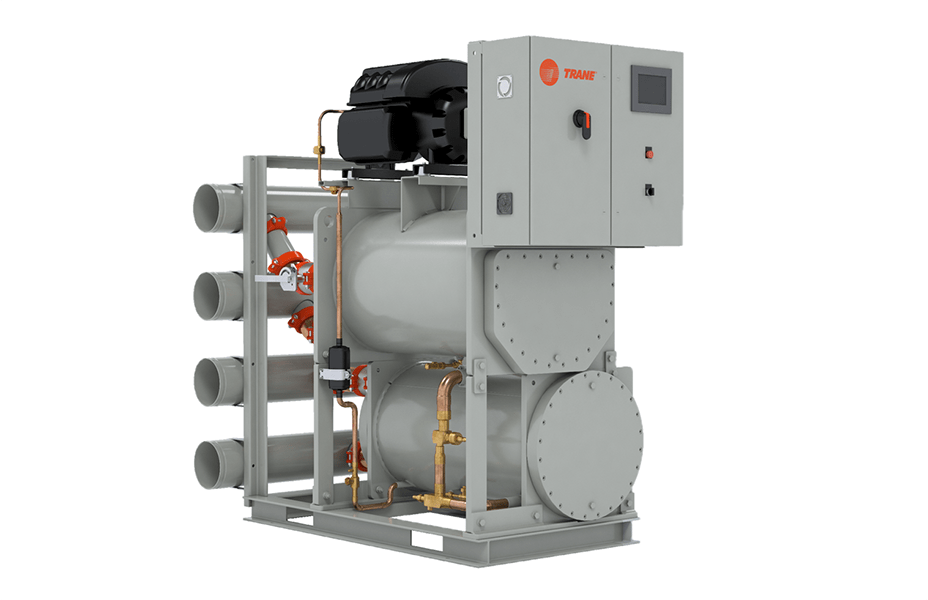

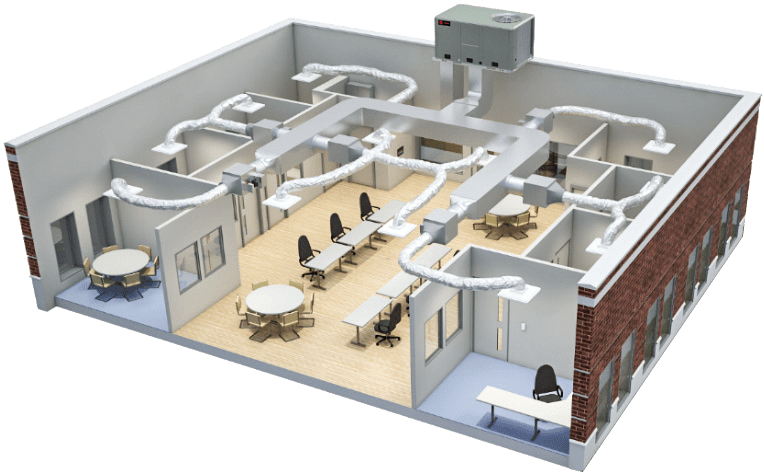

Full drop-in replacement of heat-generating fossil fuel assets like boilers is an immense and risky task. Instead, Life Science facilities should consider pragmatism and focus on de-loading boilers. Pharmaceutical operations are rife with year-round loads, simultaneous heating/cooling, and high-ventilation operational needs, which make de-loading initiatives attractive from a magnitude of impact standpoint.

Your Guide to a Successful Decarbonization Roadmap

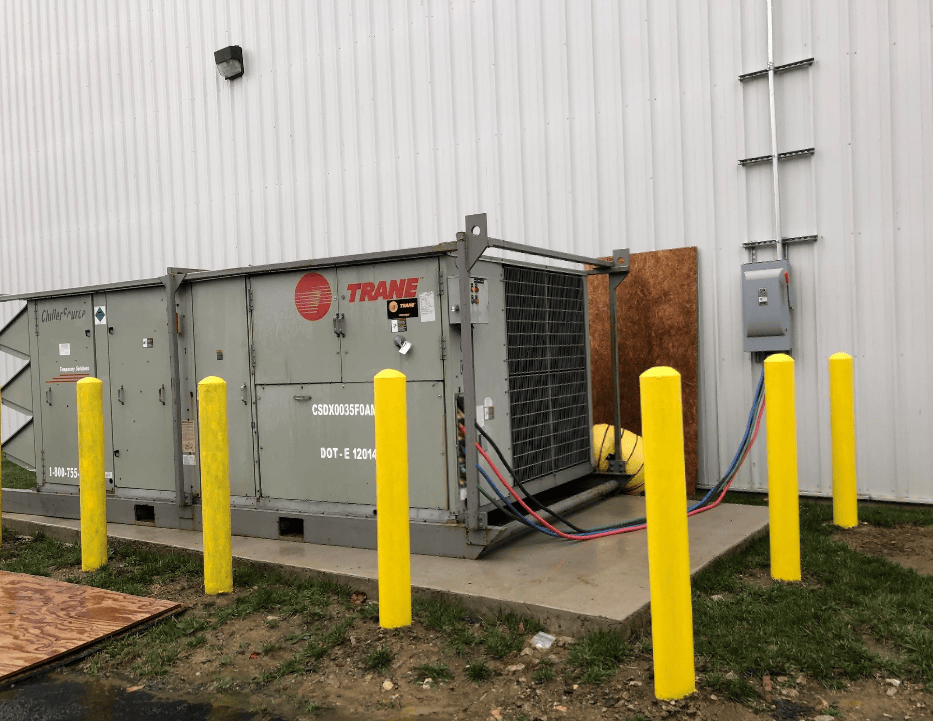

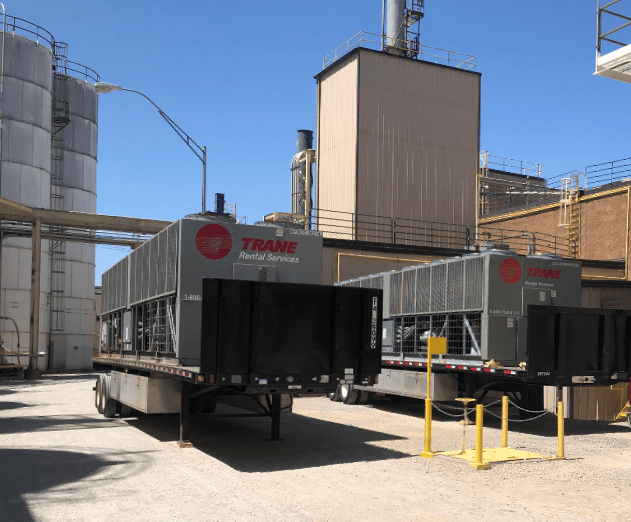

While we at Trane are focused on supporting Zero Carbon buildings of the future, the overwhelming majority of decarbonization opportunities are at existing facilities where drop-in replacements of fossil fuel fired Heating Hot Water, Domestic Hot Water, Process Water Heaters, and Air-Exhaust Recovery technologies are immediately available. Trane Engineers can provide significant insight into your facility's decarbonization roadmap and help build a project portfolio to secure capital funding and exceed the sustainability objectives of your business.